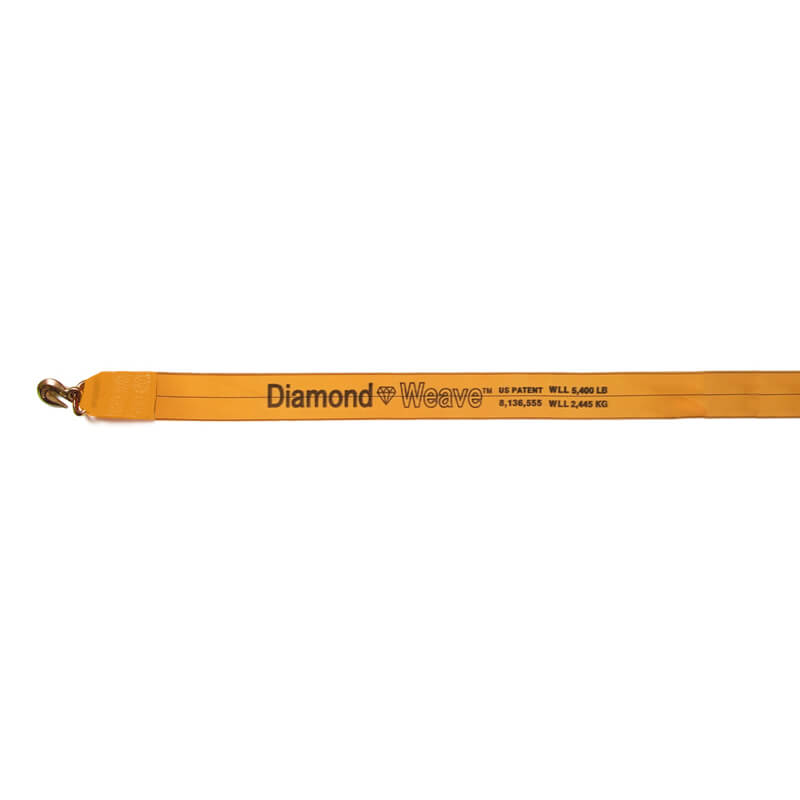

4″ x 40′ Diamond Weave™ Winch Strap with Item #416 Grab Hook Assembly

Multiprens USA’s Diamond Weave webbing is four times stronger than our standard web. It is abrasion resistant, durable and strong with very little stretch. A patented process during manufacturing allows the strap to take abrasion across the web face evenly, reducing abrasion wear.

| Weight | 3.28 kgs / 7.20 lbs |

|---|---|

| Material | Gold Diamond Weave Webbing, Gold Grab Hook Assembly (#416) |

| Color | Gold with Black Stencil and Gold Grab Hook Assembly |

Diamond Weave web has a 1/8″ stripe to help identify wear. 4x more abrasion-resistant than standard webbing; This creates a durable webbing that is very strong with very little stretch to keep your cargo secured.

Used with Multiprens #416 Grab Hook Assembly, Multiprens Diamond Weave Winch Strap will give you confidence that your load is protected and that your Diamond Weave Straps will have a long life.

Webbing Breaking Strength: 9,090 kgs / 20,000 lbs Working Load Limit: 2,455 kgs / 5,400 lbs #416 Grab Hook Assembly Breaking Strength: 7,363 kgs / 16,200 lbs

Standard Skid Pack Quantity: 10

Unit Packaging: Individually

Standard Pack Unit Quantity: 1

Webbing strap assemblies must be protected when used on or over corners, edges and rough or sharp objects. All strap assemblies require inspection each time before they are used.

Straps that are cut, worn or otherwise damaged shall not be used.

Strap assemblies should never be tied into knots or allowed to become knotted.

All Multiprens USA straps are load control devices and should not be used for overhead lifting.

Synthetic web tie down assemblies should not be loaded in excess of the Working Load Limit. Consideration should be given to the angle from the vertical (cargo tie down to load angle) which affects working load limit capacity.

Synthetic web tie downs shall be used, checked and adjusted during transportation of cargo per federal, state, Provencal, local and industry regulations.

All webbing strap assemblies or systems are only as strong as the weakest component, including the point of attachment.

When tie downs are attached directly to cargo, they should be attached symmetrically and above the cargo’s center of gravity to reduce the tendency of cargo to overturn.

Do not repair webbing, hardware or stitching / sew patterns.

All users must be trained in tie down selection, use and inspection, cautions to personnel, environmental effects, all applicable standards, regulations and tie down practices.

Be alert to hazards when securing cargo.

Tie downs should be protected from mechanical, chemical and environmental damage.

Tie down straps should be removed from service:

The identification tag is missing or not readable.

Holes, tears, cuts, snags or embedded materials are present.

Broken or worn stitches in the load bearing splices.

Knots in any part of the webbing.

Excessive abrasive wear or crushed webbing.

Signs of ultraviolet (UV) light degradation.

Distortion, excessive pitting, corrosion or other damage to buckles or end fittings.

Any conditions which cause doubt as to the strength of the tie down.

All Multiprens USA products shall be used in accordance with local, state, federal, and industry regulations. It is the owner and / or users responsibility to evaluate the suitability of any cargo-securing product for their particular application. Failure to follow instructions and warnings or proper use, care and inspection criteria could result in cargo damage, severe personal injury or death.